The "green account" of the food industry: save a tree with less than a ton of paper

Release time:

2020-07-16

China Economic Network, Beijing, May 30 (Reporter Duan Danfeng) recently, during the sixth collective study of the political Bureau of the CPC Central Committee, General Secretary Xi stressed that we should adhere to the basic national policy of saving resources and protecting the environment, strive to move towards a new era of socialist ecological civilization, and put forward a circular economy development mode of reduction, reuse and resource utilization. At present, people have increasingly felt the pressure brought by resources and environment, and governments and enterprises have set foot in the field of environmental protection. With the increasing awareness of environmental protection, all walks of life are stepping up the research and development of various green products. And "green packaging" is today and the future of the entire twenty-first century packaging industry should strive for the goal. Due to the further development of China's socialist market economy and the growing voice of global environmental protection, the market competition around environmental protection will become more intense. As far as various products are concerned, this competition is no longer only the traditional concept and form, that is, the competition of product quality, product value and product appearance, but more importantly, whether it meets or is conducive to the competition of environmental protection requirements. The two major international and domestic markets in the 21st century will be a market that will gradually evolve to "green. In this market form, environmentally friendly products will increasingly occupy the dominant position in the market. The green revolution in the food industry has never stopped. In the face of resource shortages and environmental pollution deterioration, green production has gradually become the goal pursued by many food companies. Li Peisheng, former executive deputy director of the National Packaging improvement Office of the State Council, said in an interview that food packaging is the main focus of the food industry for energy conservation and emission reduction and the development of circular economy. With the progress of technology, China's food packaging level has stood in the forefront of the world. "Except for disposable foamed plastic tableware 15-20 years behind foreign countries, the other is basically the world's latest technology, and it can ensure green safety".

It is understood that in the beverage industry, packaged drinking water has accounted for 43%. Since 2011, the China Beverage Industry Association has taken the lead in drafting the "Comprehensive Energy Consumption Limit for Beverage Manufacturing" and issued by the Ministry of Industry and Information Technology. Add an assessment to the domestic beverage production and sales system. The assessment content includes: the utilization rate of raw and auxiliary materials; the water intake per unit of product, the comprehensive energy consumption per unit of product; the utilization of water resources, wastewater treatment and discharge standards, and solid waste The level of energy conservation and environmental protection of the management and equipment; and through clean production measures such as changing the production process, produce products that save costs and reduce energy consumption. Zhao Yali, chairman of the China Beverage Industry Association, said that energy conservation and emission reduction in the beverage industry is not only to build a "green factory", but also to extend the concept of "green" to the logistics, procurement, sales and consumption of products, so as to explore a new way to "build a green chain of beverage products from production to consumption. At the same time, she pointed out that in the development of packaged drinking water for nearly two decades, changes have taken place in the consumption environment, water resources environment and natural environment, and they are constantly improving their social responsibility. practical actions have been taken in production and marketing.

In addition to the concept of green factories, from an international perspective, the use of recycled paper in the food industry is also a basic trend. In recent years, advanced countries have begun to take advantage of the increase in the use of recycled paper to show environmental protection. Among them, industry association information pointed out that the utilization rate of recycled paper in Germany exceeds 70%, Japan exceeds 50%, 5. the global average is more than 44%, while China only has 27%. In this regard, Li Peisheng also said, "virgin pulp paper needs about 6000-7000 yuan per ton, while recycled paper only needs 2000-3000 yuan, a difference of 50%-60%, and the economic benefits can be significantly improved. Therefore, recycled paper is an important part of the country's development of circular economy." It is known that 0.9 billion trees are converted into pulp and paper every year, and the use of recycled paper can effectively reduce tree felling. The energy consumed in the production of recycled paper is only 1/3 that of ordinary paper. The use of every ton of recycled paper means saving 4400 degrees of electricity, 30000 liters of water, and saving 19 trees.

In China, the convenience food industry is the largest use of "paper bowls" and "paper cups. In 2011, China's instant noodle industry used a total of about 10 billion copies of paper containers, which is the largest industry in food paper containers. At present, the domestic mainstream instant noodle production enterprises have continuously adopted advanced production technology. For example, some enterprises have reduced their dependence on virgin pulp under the condition of ensuring food safety through double-layer hollow design. Through the use of recycled paper, as the largest instant noodle manufacturer, Master Kang's spokesman Chen gongru said that through the use of recycled paper on the outer layer of the instant noodle paper barrel, the felling of nearly 650000 trees has been avoided every year, and the additional electricity and water 2/3 required for the production of raw paper have been greatly saved.

For the use of recycled paper, Wang Zhutian, assistant director of the National Food Safety Risk Assessment Center, once said that the paper container of instant noodles in my country is composed of an inner "paper bowl" and an outer "bowl label". Products that meet relevant standards can fully guarantee food safety.

Therefore, the enterprise uses recycled paper as the packaging material of the outer layer of the instant noodle paper barrel, which basically takes into account the food safety and the reuse of resources, and is a demonstration case of practicing circular economy.

Li Peisheng also said that the use of recycled paper for instant noodle packaging is more about energy conservation and environmental protection. In the long run, it is conducive to the development of the industry's circular economy, and it can also reduce costs, so that consumers from all walks of life can enjoy cheap and high-quality products anytime and anywhere. However, whether it is the use of recycled paper or raw pulp paper as packaging, as long as it is in line with national standards, it is safe to add in excess. "National standards are developed after years of research by enterprises and experts, and they are not thought of by beating their heads". Zhao Yali believes that Chinese Dream should be reflected in every detail and to ensure food safety, first of all, enterprises must take the initiative to assume greater social responsibility at the source and in all production links, and improve the level of fulfilling social responsibility.

Recommended News

Paper bag machine industry dynamics

2024-07-28

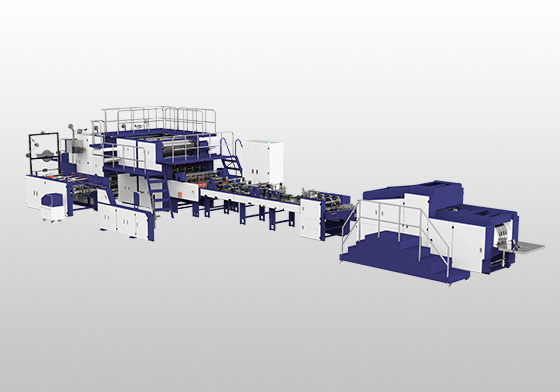

ZD-F190 roll square bottom paper bag machine

2019-10-22

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.