Nanjing Zono Machine Equipment Co., Ltd.

Condensing Seiko ● Excellent Super Energy

Specializing in full automatic paper bag machine series equipment R & D manufacturing and sales

About Zhuoneng

company was founded in 1997 and was initially engaged in the production and sales of precision parts. In 2002, he began to engage in the R & D, manufacturing and sales of full-automatic Chinese and Western envelope machine equipment. In 2008, due to the needs of the company's development, he moved from Wenzhou to Nanjing Gaochun Development Zone and established Nanjing Zhuoneng Mechanical Equipment Co., Ltd., specializing in the R & D, manufacturing and sales of full-automatic paper bag machine series equipment. Since its establishment, the company has been implementing the business philosophy of "based on the market with quality, winning customers with service, creating brands with reputation, and leading development with innovation. Grasp the company's internal management, and strictly implement the ISO9001 quality system standards and CE safety certification, in recent years have been successively obtained and recognized as high-tech enterprises, intelligent packaging engineering technology research center, enterprise technology center, enterprise industrial design center, China's high-quality products, Jiangsu quality integrity 5A brand enterprises... There are nearly 20 patents.

The company was established in 1997

26 years of industry experience

A number of invention patents

Existing employees of the enterprise

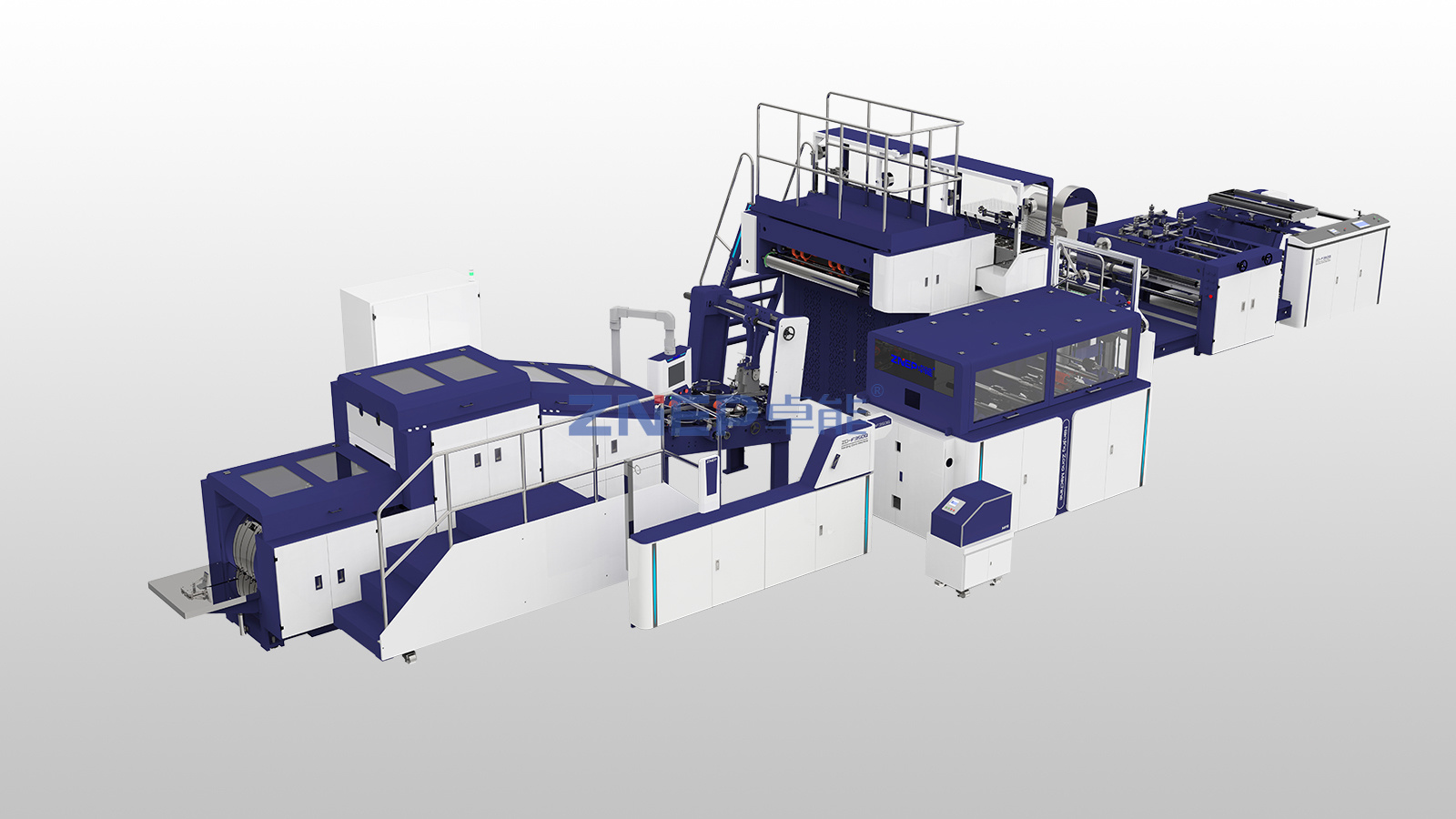

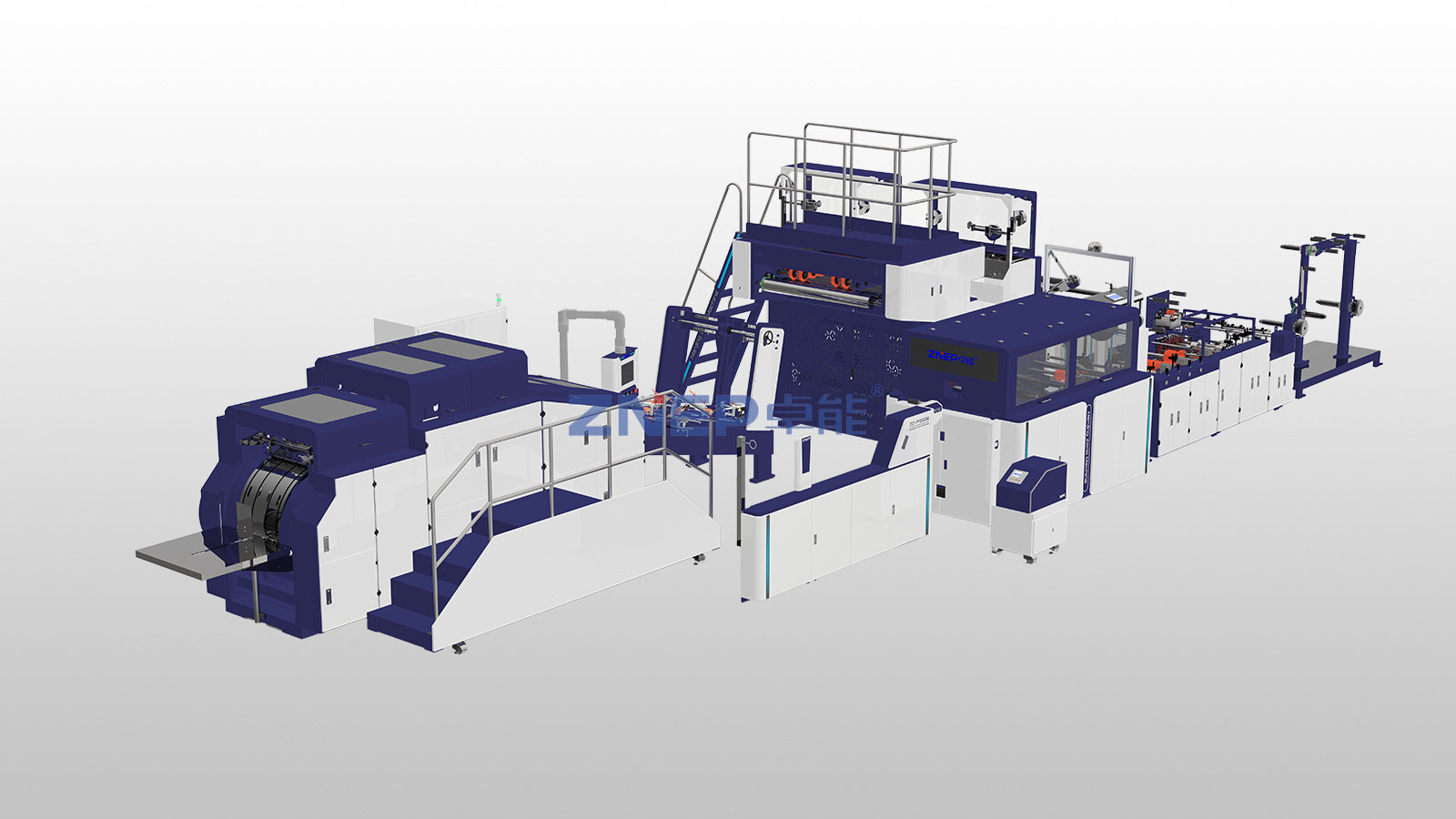

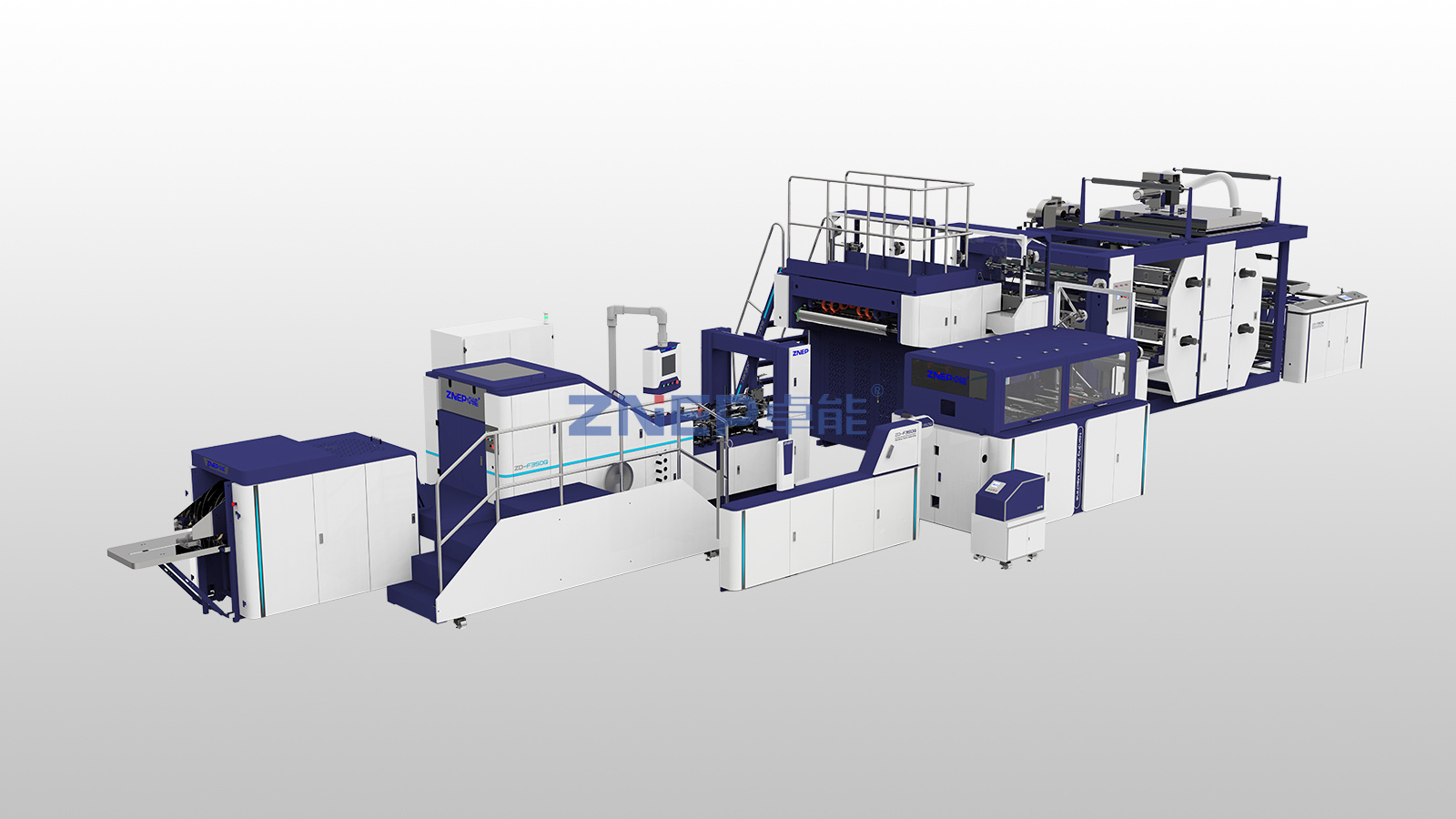

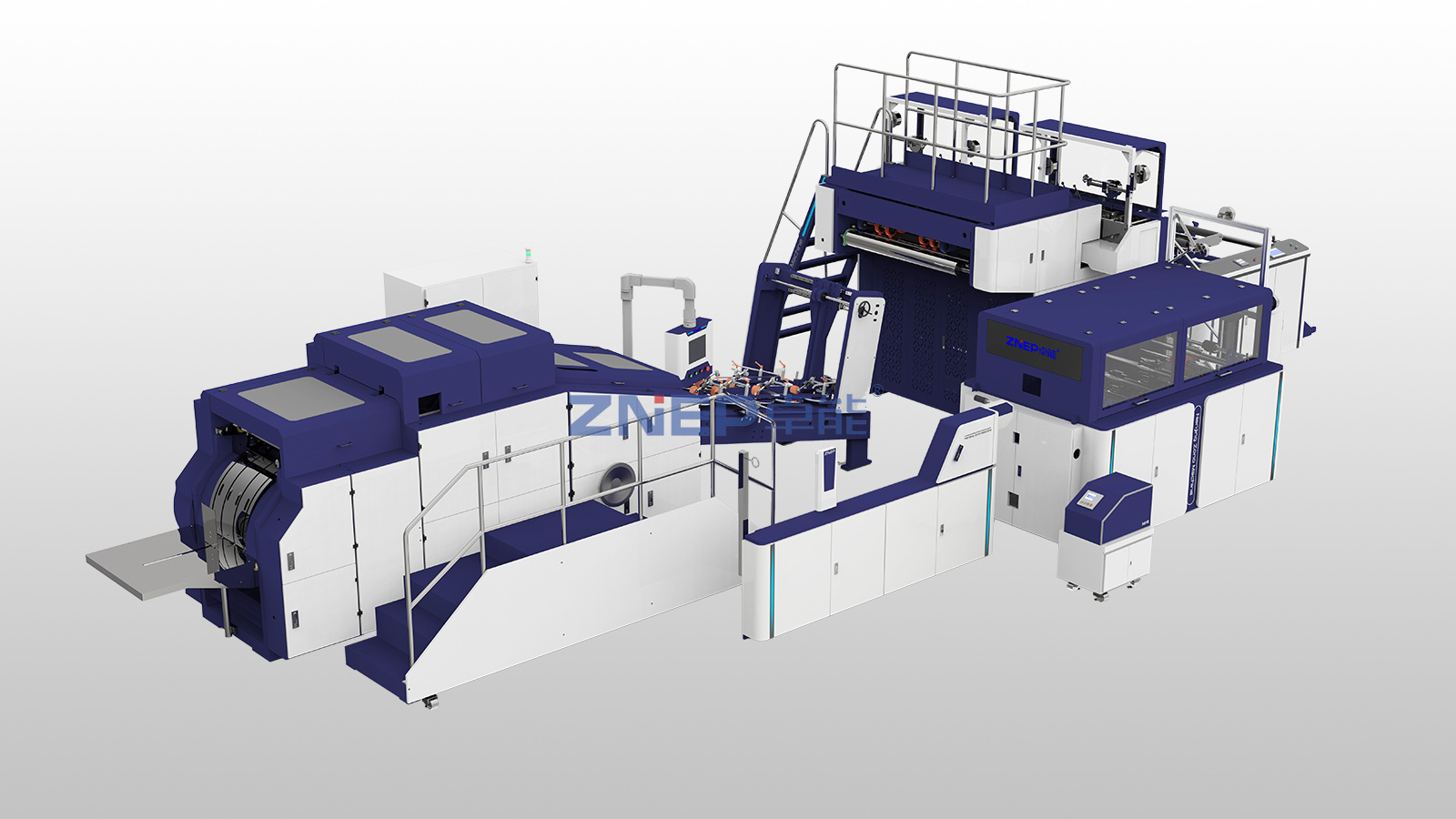

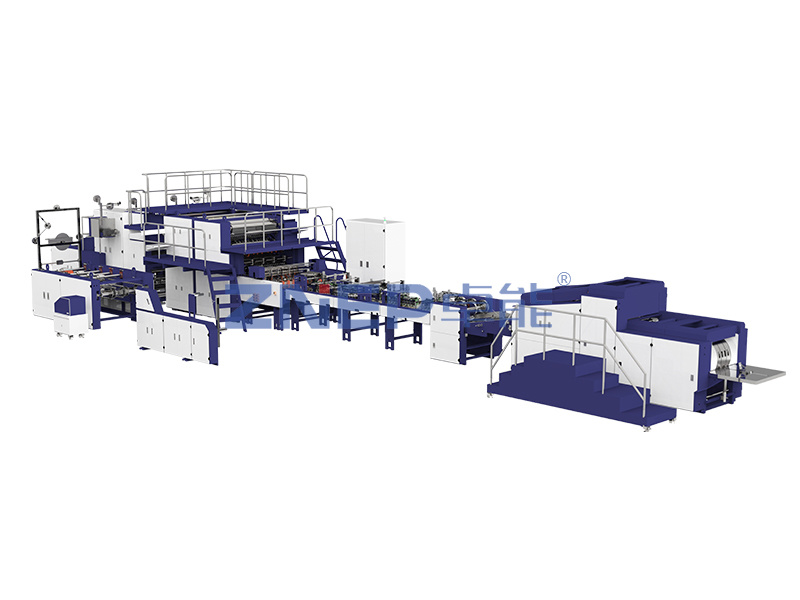

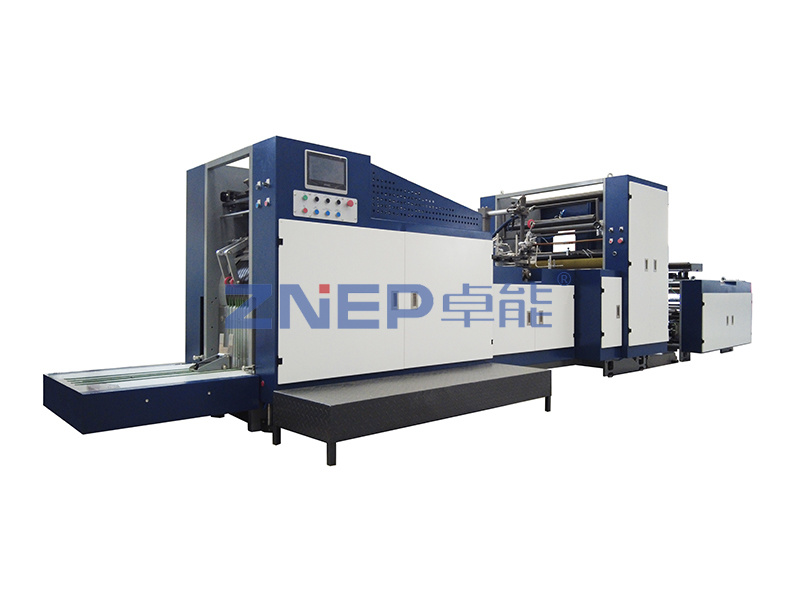

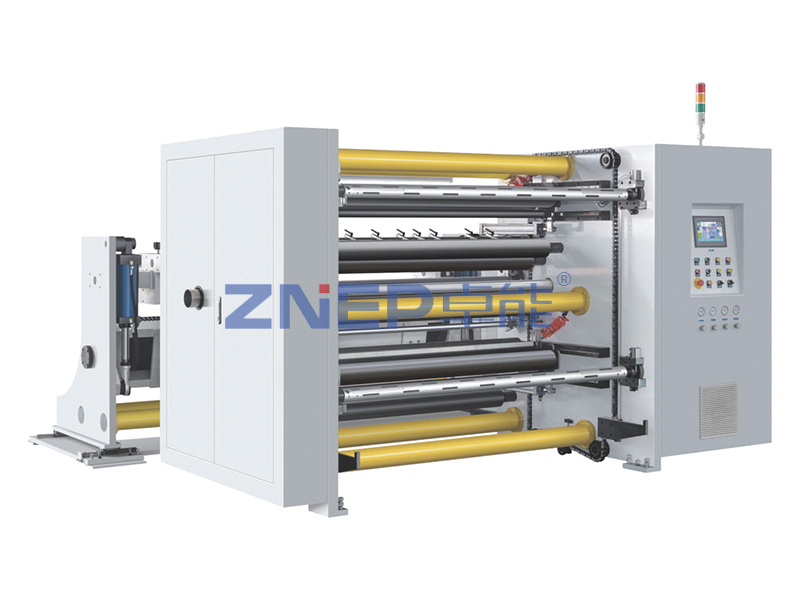

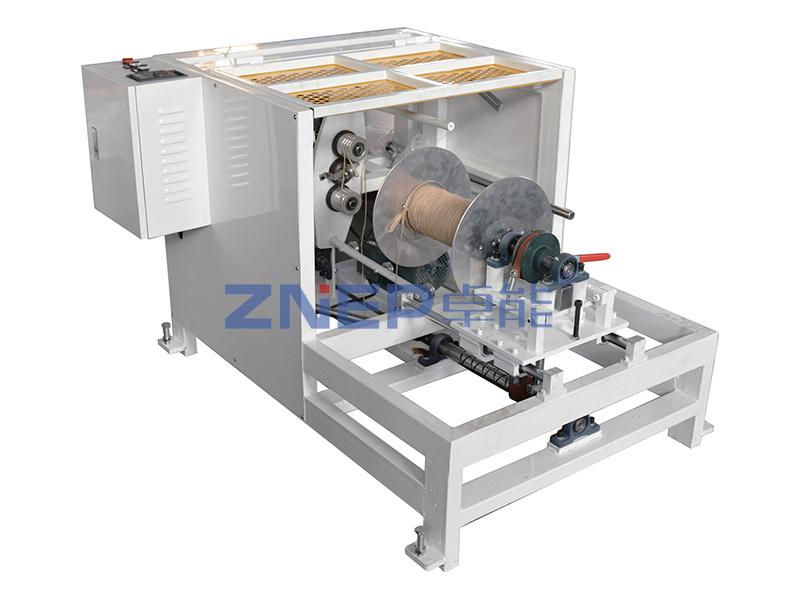

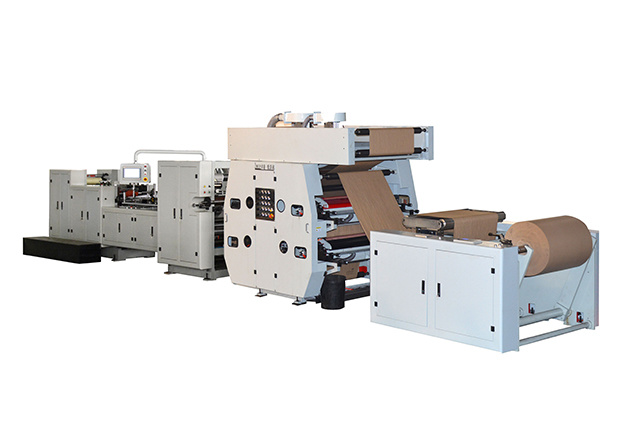

Equipment Display

Recommended Equipment

specializes in the development of automatic paper bag machine series equipment manufacturing and sales.

Honors

company has been implementing the business philosophy of "based on the market with quality, winning customers with service, creating brand with reputation, and leading development with innovation. Grasp the company's internal management, and strictly implement the ISO9001 quality system standards and CE safety certification, in recent years have been successively obtained and recognized as high-tech enterprises, intelligent packaging engineering technology research center, enterprise technology center, enterprise industrial design center, China's high-quality products, Jiangsu quality integrity 5A brand enterprises... There are nearly 20 patents.

Customer Photo

We have clients worldwide, for example, South-East Asians such as South Korea (DaeguPaju-si), Vietnam, Cambodia, Philippines, India (Mumbai, New Delhi), indonesia, Pakistan;European countries such as Spain (Madrid, Tenerife), Portugal, Finland, Ukraine, Turkey(lstanbul, Konya); North America such as USA, Canada (Toronto, Trois-rivers, Winnipeg);South America such as Uruguay, Chile, Guatemala; Mid East such as Palestine, Syria,African countries such as Tanzania (Arusha, Moshi), Kenya (Nairobi, Nakuru, Malindi),Algeria, Cote D'lvoire, Morocco (Tangier, Casablanca). Domestic cooperative customerssuch as some listed enterprises, and well-known enterprises in the industing packagingand printing.

Enterprise Culture

Mission: Make our Zhuoneng Paper Bag Machine Specialize in Excellence and Achieve World-renowned

Vision: Let Users Who Buy Our Paper Bag Machine Obtain Real Value; Let's get better development opportunities for our employees who are willing to work hard

Values: Take the right path, be mindful and do justice

Talent Concept

Reuse outstanding talents without sticking to one pattern, and build a high-energy team with sincerity

Establish a modern enterprise system and create an excellent enterprise culture

Create a learning enterprise and cultivate an innovative mechanism

Enterprise Advantage

Design

The paper bag machine is highly specialized, so the most important thing is to design the structure and principle of the components of each part of the paper bag machine very reasonably. The rationality of the structure and principle is directly related to the use function, production efficiency, stability and operability of the equipment, as well as the service life of the equipment and the durability of its spare parts. This is what every member of our technical department should take seriously and do.

Supply

That is, the purchasing department strictly selects raw materials with guaranteed quality according to the design requirements of the technical department. The purchase of each raw material must be analyzed for chemical composition and compared and checked for data rationality. Some materials such as castings must undergo constant temperature heat treatment and aging treatment for more than half a year. Only in this way can the quality of subsequent parts be guaranteed by strictly controlling the source of raw materials.

Finishing

The finishing workshop is constructed strictly according to the drawings and uses modern and advanced vertical and horizontal CNC machining centers to control the precision of each part. The finished parts shall be inspected and tested by professional and targeted instruments, such as micrometer, dial indicator, three-coordinate, dynamic balance and other equipment and instruments used to inspect and test the various indexes and process requirements of the parts, each index and data must strictly meet the requirements of the drawing before it is considered as a qualified product, and then the body of some parts can be put into storage after being marked with the above number by laser printing.

Assembly

After the parts of all sets are in place, they will be assigned to the assembly teams of each set for assembly. Each assembly team will carry out various assembly work strictly according to the assembly drawings provided by the technical department. After the assembly is completed, the whole machine will be assembled and energized. After the preliminary functional test and the inspection of the functional components of each part and set of the whole machine are completed, they will be handed over to the debugging and final inspection work.

Debugging

The assembled whole machine will be carefully debugged, correspondingly check whether all parameters and indexes of the paper bag machine meet the technical requirements, check whether there are abnormal phenomena in all parts and sets of functions, and then test the production speed and stability of the paper bag machine. Only after each link has been checked to meet the technical design requirements can the paper bag machine be qualified for delivery.

News

10

/

10-22

Zhuoneng Dynamic

10

/

10-28

Zhuoneng Dynamic

11

/

11-06

Zhuoneng Dynamic

11

/

11-11

Zhuoneng Dynamic

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.