Market Prospect of Vacuum Packaging Machine Industry

Release time:

2020-07-15

1. vacuum packaging machinery. Many enterprises producing vacuum packaging machinery in China are mainly assembled, the main varieties are semi-automatic operation, fully automatic continuous, large vacuum chamber and vacuum packaging machinery suitable for liquid packaging are few, and there is a general lack of efficient and special vacuum packaging machines in China.2. bag making, filling and sealing packaging machinery. At present, there are more than 100 domestic manufacturers of such machinery, with an annual output of 15 million units. The development trend of bag making, filling and sealing packaging machinery is modular structure, multi-column high speed, high stability, simple transmission machinery and adaptive closed-loop control.3. metal packaging container processing equipment. China's metal packaging container processing machinery manufacturing industry has begun to take shape, the development trend of such products is to improve product performance, improve the yield and material utilization rate, the second is to accelerate product technology improvement, the development of mercury-free welding and high-performance high-frequency welding power supply.4. corrugated box (board) production equipment. In the past ten years, China's corrugated box machinery industry has developed rapidly. The product categories have developed from corrugated cardboard lines to printing slotting machines, cardboard gluing machines, corner cutting machines and other varieties. The future development direction is high-speed complete sets of equipment, and the second is medium and light corrugated cardboard box complete sets of equipment.5. pulp molding processing equipment. The current production scale of China's paper tableware processing equipment is still relatively small, and the price of processing equipment is high. In the future, pulp mold tableware processing machinery should increase research on reducing the cost of forming heating molds, improving heating methods, reducing power consumption costs, and increasing production.

Recommended News

Paper bag machine industry dynamics

2024-07-28

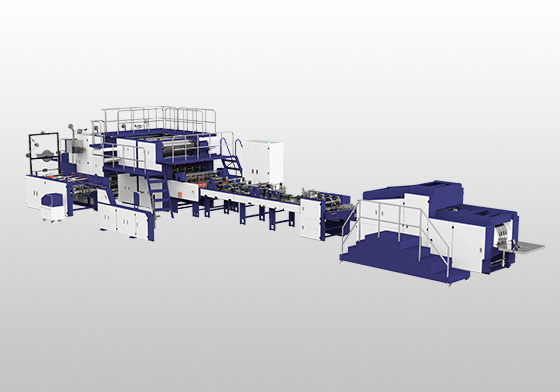

ZD-F190 roll square bottom paper bag machine

2019-10-22

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.