Food and beverage plastic packaging industry is developing in the direction of environmental protection

Release time:

2020-07-15

1, high barrier, multi-functional film technology continues to improve. Its soft plastic packaging materials have become a hot spot of domestic development in recent years, including high permeability, multi-functional cling film, aseptic packaging film and so on. With the bag making and printing technology on a new level, it has entered the era of "color revolution", which has promoted the development of soft plastic packaging products to a deeper and higher grade.2. The development of multi-layer co-extrusion technology has changed the product structure of functional films and containers. With the increasing demand for environmental protection, it is necessary to minimize the amount of garbage generated under the premise of meeting the packaging function. Co-extruded packaging film, its process equipment investment, low production costs, strong adaptability, convenient operation, there is no environmental pollution problems. Therefore, the international co-extrusion technology is developing rapidly. The data show that the developed countries co-extrusion packaging film accounts for about 40% of all soft plastic packaging film, while China is only about 6%, obviously the proportion of the two is unreasonable. The development of co-extruded packaging film will also change the product structure of multifunctional film, which is suitable for food packaging such as beverages, milk, and fresh meat.3, fruits and vegetables fresh packaging film market prospects. China is a big country in the production and sales of fruits and vegetables in the world, but about 30% of the water is lost in the process of storage, transportation and sales, and improper packaging is one of the reasons for the loss of fruit decay. Although the physiological properties of different fruits are different, water loss, discoloration, taste change and decay are common problems. Therefore, in-depth study of inhibiting metabolic processes, reducing the consumption of nutrients, and maintaining the flavor quality of fruits are important issues for fresh-keeping packaging. At present, polyethylene film and polypropylene film are the most widely used packaging materials for fresh fruits and vegetables. The market space for plastic containers is vast, among which the beverage industry has attractive business opportunities, and the demand for plastic containers such as soda, juice and beverages is increasing day by day. After investigation, China's beverage production is increasing at a rate of more than 20% every year, and the market prospect of PET bottles in carbonated beverage packaging is very promising. The development of polypropylene transparent packaging bottles is a hot spot in domestic plastic packaging products in recent years. With the successful development of transparent modifier nucleating agent, high transparent PP can be widely used in blowing, blowing, extrusion, thermoforming and other ways to make containers, used in food, medicine and other industries, its price is appropriate, PS, ABS, PET and PE container competitors, with broad market prospects. In recent years, the use of heat-resistant polyester bottles (PET) for beer packaging has developed rapidly in the world, especially PET bottles using plasma coating technology, and their permeability can almost reach the same level as glass. At the same time, polyester bottles can also be treated with high temperature sterilization, expanding its scope of application. Also suitable for filling tea drinks and other packaging. In addition, the new polyester bottle of polyethylene glycol (PEN), which has attracted the attention of the packaging industry, is also entering the beer industry. It can fundamentally solve the explosion problem of beer bottles and will be a "major revolution" in beer packaging ".6, drinking water bottles (barrels) The 5-gallon drinking water barrels on the market are mainly PVC and PET. In recent years, PC drinking buckets have developed rapidly, with Shanghai and Guangdong alone producing more than 50 million buckets. Therefore, with the production of domestic raw materials, the development of PC beverage bottles (barrels) will be a rare opportunity.Conclusion: No matter what kind of plastic packaging is used, it must meet the requirements of green packaging: reducing waste pollution; solving the environmental protection problem of solvents; recycling and reuse. Meet the requirements of environmental protection, pollution-free green packaging, will be more and more social attention. Therefore, we should vigorously develop green packaging, do a good job of packaging waste treatment and resource recycling, to achieve sustainable development requirements.

Recommended News

Paper bag machine industry dynamics

2024-07-28

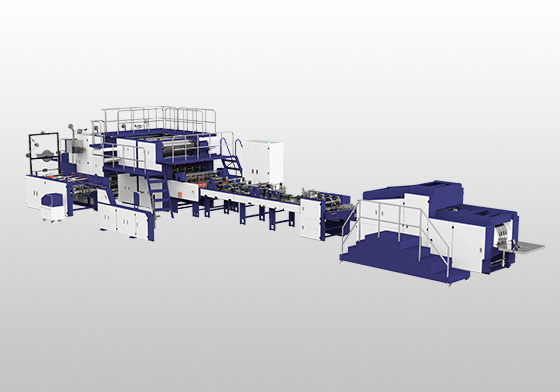

ZD-F190 roll square bottom paper bag machine

2019-10-22

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.