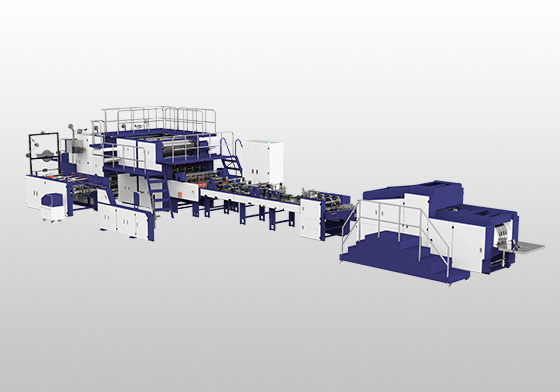

Daily maintenance method and step sequence of packaging machinery and equipment

Release time:

2020-07-16

packaging machinery. They are the cleaning, fastening, adjustment, lubrication and anti-corrosion work of the equipment. In the normal production process, the machine maintainer should do: according to the maintenance manual and maintenance procedures of the machine packaging equipment, strictly implement various maintenance work within the specified period, reduce the wear rate of parts, eliminate the hidden dangers of failure, and extend the machine Life. The maintenance work of

machinery includes routine maintenance, regular maintenance and special maintenance. Regular maintenance can be divided into three categories: primary maintenance, secondary maintenance and tertiary maintenance. Special maintenance can be divided into seasonal maintenance and disabled maintenance. The following article will introduce the specific procedures and precautions for these types of maintenance work.

The routine maintenance of packaging machinery focuses on cleaning, lubrication, inspection and fastening. Routine maintenance must be carried out as required during and after the machine is working.

level maintenance work is carried out on the basis of routine maintenance, and the key work content is lubrication, fastening and inspection of all relevant parts and their cleaning work.

secondary maintenance work to check, adjust the focus. Specifically, check the engine, clutch, transmission, transmission components, steering and braking components.

Three-level maintenance focuses on detection, adjustment, troubleshooting hidden dangers and balancing the degree of wear of various components. It is necessary to carry out diagnostic testing and state inspection on the parts that affect the performance of the equipment and the parts with fault signs, and then complete the necessary replacement, adjustment and troubleshooting.

Seasonal maintenance refers to the inspection and repair of components such as power system (engine), conveying system (screw shaft and belt conveying), air pressure system (check the lubrication and sealing of air compressor) and control system (maintenance of Youte electromechanical control cabinet, which shall be completed under the guidance of Youte after-sales engineer) before summer and winter.

stop maintenance refers to the packaging equipment due to seasonal factors (such as winter break) and other need to stop for a period of time, should do a good job of cleaning, cosmetic, matching, moisture-proof, anti-corrosion and other work.

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.