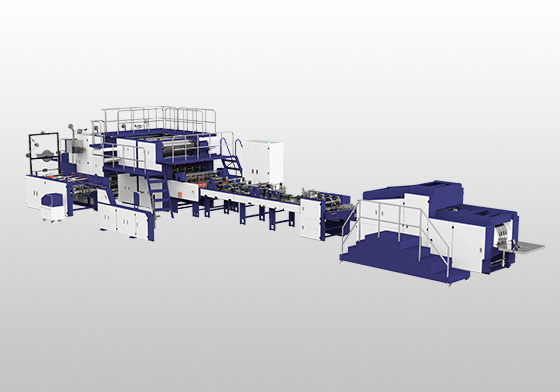

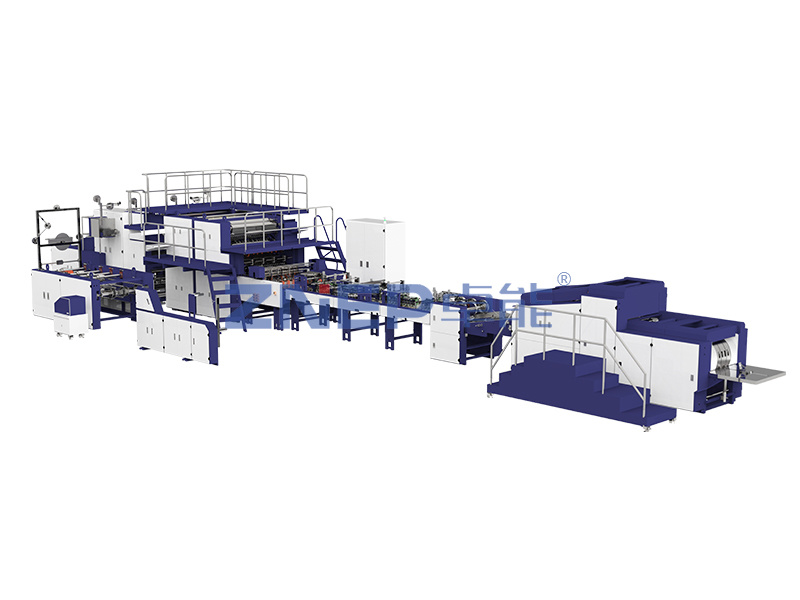

Automatic Handle Making Machine

Key words:

paper bag machine

Classification:

Product Details

Product Introduction

The machine is used to produce hand-held paper bags with hand-held tongue. The hand-held station automatically makes the prepared round rope and roll paper into hand-held. Through the conveying system, the prepared hand-hold will be transferred to the work stations of cutting handle, sending handle pasting handle and pressing handle, and then the primary color or printed web will be used to open the window of the tongue and absorb waste, glue paste, easy tear line pre-prick, tongue position pre-prick, patch avoid rope position broken, patch position glue, automatic paste hand-hold, then, the main machine will apply edge glue, form a cylinder, break, cut, crease, apply glue at the bottom, form the bottom of the bag and transport the paper with hand in hand out of the bag. The whole process is completed synchronously at one time. Truly fully automated production, can effectively save labor costs.

The whole machine adopts the Japanese servo electronic control system to ensure that the whole machine can run quickly and stably, and can effectively reduce the time of paper bag size adjustment. The production of paper bags and finished products with high accuracy, strong stability, easy maintenance, and efficient production. It is an ideal purchase equipment for major printing plants and paper bag manufacturers.

Product Parameters

| Main technical parameters | ZN-S100Y |

| Paper rope spacing (A) | 108mm |

| Paper Rope Width (B) | 12mm |

| Paper Rope Height (C) | 100mm |

| Paper width (D) | 40mm |

| Paper Length (E) | 190-170-152mm |

| Paper Rope Length | 352mm |

| Paper thickness | 90-130g |

| Bag width | 200-450mm |

| Bag height | 200-450mm |

| Production speed | 33-40pcs/min |

| Total power | 12.2KW,50HZ |

| Servo motor power | 750W two group |

| Overall dimension/Over dimension | L7000xW2450xH1700mm |

Related Products

Get Free Product Quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call our service hotline

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.