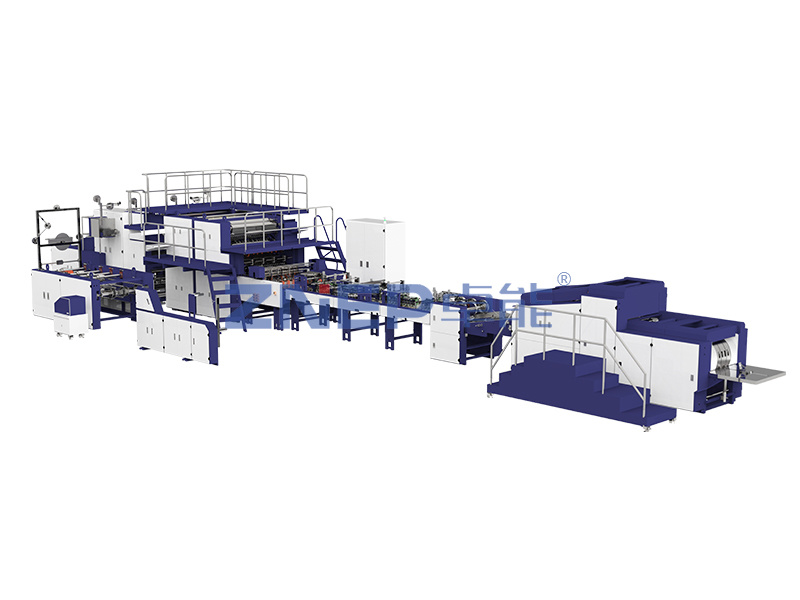

Round & Flat Rope Tongue Fully Automatic Paper Bag Machine

This machine is used to produce paper bags with hand grips and tongue openings. The hand grips are automatically made from prepared round ropes and roll paper pieces at the hand grip station. The completed hand grips are then conveyed to the cutting, sending, pasting, and pressing stations. The original color or printed roll paper undergoes window waste suction, glue application for pasting, easy-tear line pre-punching, tongue position pre-punching, patch avoidance for rope position point cutting, patch position glue application, and automatic pasting of hand grips. The main machine then applies edge glue to the paper with hand grips, forms it into a tube, tears it, cuts it, creases it, applies glue to the bottom, shapes the bag bottom, and finally conveys the finished bag out. The entire process is completed in one synchronized operation, truly achieving fully automated production and effectively saving labor costs.

Key words:

paper bag machine

Classification:

Product Details

Product Introduction

This machine is used to produce paper bags with handles and tongue openings. The handle-making station automatically forms the prepared round rope and roll paper into handles, which are then conveyed to the cutting, sending, pasting, and pressing stations. The original color or printed roll paper undergoes processes such as window waste suction, glue application for pasting, easy-tear line pre-punching, tongue position pre-punching, patch avoiding rope position cutting, patch position glue application, and automatic handle pasting. The main machine then applies edge glue, forms the tube, tears, cuts, creases, applies glue to the bottom, shapes the bag bottom, and conveys the finished bag out, completing the entire process in one synchronized operation. This truly achieves fully automated production, effectively saving labor costs.

The entire machine uses a Japanese servo control system, ensuring that it operates quickly and stably while effectively reducing the time for adjusting paper bag sizes. The produced paper bags and finished products have high precision, strong stability, easy maintenance, and high production efficiency, making it an ideal choice for major printing factories and paper bag manufacturers.

The entire machine uses a Japanese servo control system, ensuring that it operates quickly and stably while effectively reducing the time for adjusting paper bag sizes. The produced paper bags and finished products have high precision, strong stability, easy maintenance, and high production efficiency, making it an ideal choice for major printing factories and paper bag manufacturers.

Product Parameters

| Main Technical Parameters | ZD-FN380QT | ZD-FN550QT |

| Roll Paper Width | 580-1270 mm | 630-1730 mm |

| Maximum Paper Roll Diameter | φ1500 mm | φ1500 mm |

| Inner Diameter of Paper Roll | φ76 mm | φ76 mm |

| Paper Weight | 60/80-150g/m² | 80/90-150g/m² |

| Finished Bag Width | 200-380mm | 220-550mm |

| Paper Tube Length | (230 + tongue) - (655 mm including tongue & rope height) |

(380 + tongue) - (770 mm including tongue & rope height) |

| Bag Bottom Width | 75-240mm | 80-300mm |

| Flap Height | 0-80 mm | 30-80mm |

| Releasing Paper Width | 15-35mm | 15-35mm |

| Flap Paper Weight | 50-100g/m² | 50-100g/m² |

| Maximum Production Speed | 120 bags/min | 110 bags/min |

| Total Power | 380V 3P4L 56 KW | 380V 3P4L 56 KW |

| Weight | 27000 KG | 29000KG |

| Overall Dimensions | 15800*6900*3400mm | 17600*7200*3500mm |

| Flat Handle | B1 | B2 |

| Paper Weight for Handle | 100-130g/m² | 100-130g/m² |

| Flat Rope Width | 12mm | 15mm |

| Flat Handle Height | 100mm | 100mm |

| Flat Rope Distance | 76mm | 95mm |

| Diameter of Reel Paper for Handle | φ1200 mm | φ1200 mm |

| Paper Patch Weight | 100-150g/m² | 100-150g/m² |

| Roll Paper (Patch) Width | φ1200 mm | φ1200 mm |

| Handle Patch Length | 152mm | 190mm |

| Handle Patch Width | 35-50 mm | 35-50 mm |

| Rope Handle | Q3 | Q4 | Q5 |

| Handle Rope Height | 90-120mm | 90-120mm | 90-120mm |

| Handle Rope Diameter | φ3-6mm | φ3-6 mm | φ3-6mm |

| Handle Patch Length | 152mm | 190mm | 190mm |

| Handle Patch Width | 35-50 mm | 35-50 mm | 35-50 mm |

| Handle Rope Distance | 76mm | 95mm | 101mm |

| Paper Patch Roll Diameter | φ1200 mm | φ1200 mm | φ1200 mm |

| Paper Patch Roll Width | 70-100 mm | 70-100 mm | 70-100mm |

| Paper Patch Weight | 80-150 g/m² | 80-150 g/m² | 80-150 g/m² |

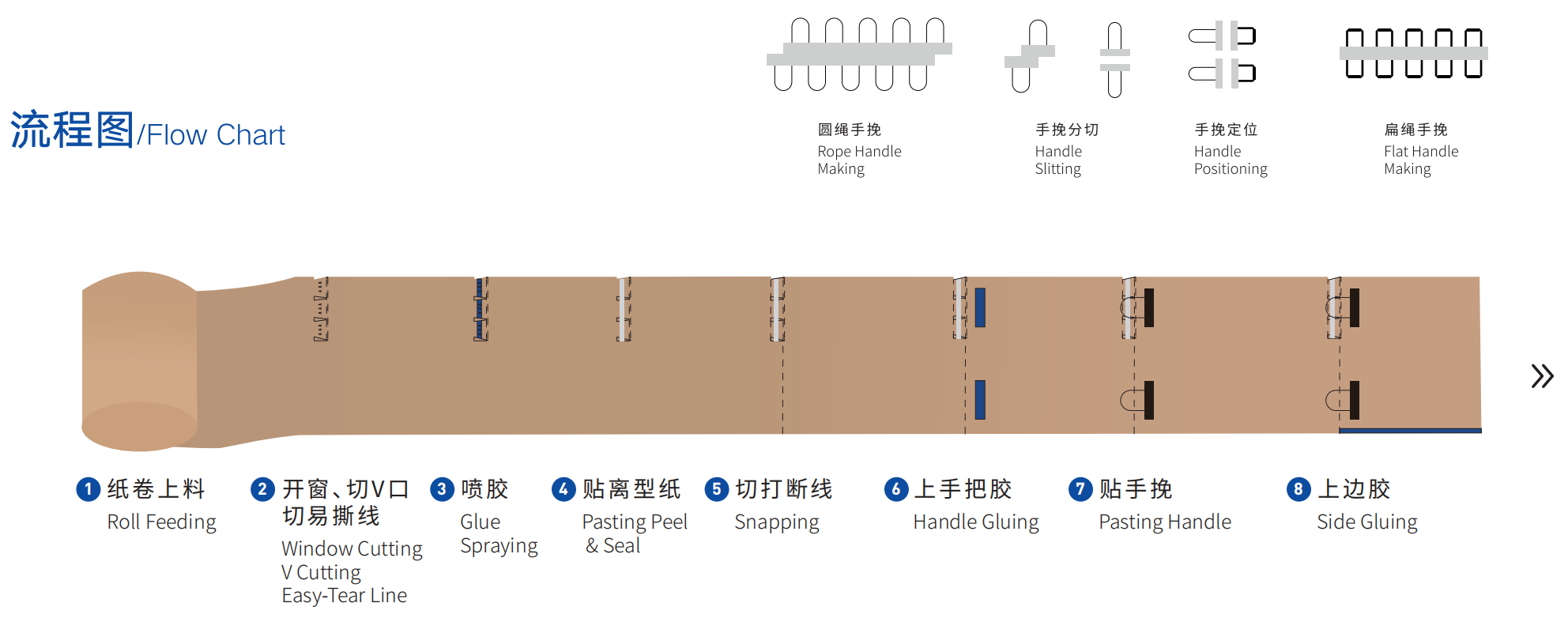

Process Flow

Related Products

Get Free Product Quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call our service hotline

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.