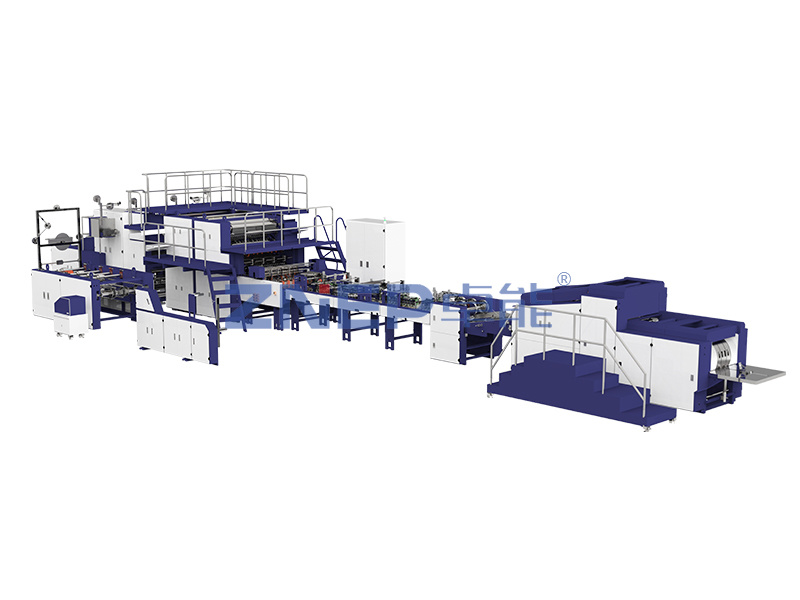

Automatic Paper Bag Making Machine With Rope/flat Handles

Key words:

paper bag machine

Classification:

Product Details

This machine is specially designed to make paper shopping bags with handles inline fully automatically. The handles will be delivered to the main machine after being produced by the handle making unit, and being cut and pasted to the paper. This machine can form the paper bag in one process from the paper roll, handle patching, side gluing, tube forming & cutting, bottom creasing & gluing and forming to bags collection.

The whole machine is in the control of servo motors (imported from Japan) to ensure the high precision and stability, simple maintenance and high efficiency. Thus it is an ideal equipment for printing houses and paper bagmanufacturers.

Product Parameters

| Main technical parameters | ZD-F230Q | ZD-F350Q | ZD-F450Q |

| Roll paperwidth | 290-790 mm | 420-1090 mm | 650-1370 mm |

| Max.dia ofpaper roll | φ1500mm | φ1500mm | φ1500mm |

| Inside dia of paper roll | Φ76mm | Φ76mm | Φ76mm |

| Paper gram | 50/65-150g/m² | 60/80-150g/m² | 80/90-150g/m² |

| Finished bag width | 80/110-230mm | 130/180-350mm | 220-450mm |

| Paper tube length | 190-(450mm including rope height) | 260mm-(530mm including rope height) | 280-(630mm including rope height) |

| Bag bottom width | 50-150mm | 65-180mm | 80-220mm |

| Max production speed | 160 bags/min | 150 bags/min | 140 bags/min |

| Working air current | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa |

| Total power | 380V 3P4L 30KW | 380V 3P4L 32KW | 380V 3P4L 32KW |

| Weight | 18500KG | 19500KG | 20500KG |

| Overall dimensions | 12300*5800*2700 mm | 13400*5900*2800 mm | 14200*6000*2900mm |

| Flat handle | B1 | B2 |

| Paper gram for handle | 100-130g/m² | 100-130g/m² |

| Flat rope width | 12mm | 15mm |

| Flat handle height | 100mm | 100mm |

| Flat rope distance | 76mm | 95mm |

| Dia of reel paper for handle | Φ1200mm | Φ1200mm |

| Paper patch gram | 100-150g/m² | 100-150g/m² |

| Roll paper(patch)width | Φ1200mm | φ1200mm |

| Handle patch length | 152mm | 190mm |

| Handle patch width | 35-50mm | 35-50 mm |

| Rope handle | Q1 | Q2 | Q3 | Q4 | Q5 |

| Handle rope height | 70-100mm | 70-100mm | 90-120mm | 90-120m | 90-120mm |

| Handle rope diameter | Φ2.5-6mm | φ3-6mm | φ3-6mm | φ3-6mm | φ3-6mm |

| Handle patch length | 95mm | 114mm | 152mm | 190mm | 190mm |

| Handle patch width | 35-50 mm | 35-50 mm | 35-50 mm | 35-50 mm | 35-50 mm |

| Handle rope distance | 47.5mm | 57mm | 76mm | 95mm | 101mm |

| Paper patch roll dia | Φ1200mm | φ1200mm | φ1200mm | φ1200mm | Φ1200mm |

| Paper patch roll width | 70-100 mm | 70-100 mm | 70-100 mm | 70-100 mm | 70-100 mm |

| Paper patch gram | 80-150g/m2 | 80-150g/m2 | 80-150 g/m2 | 80-150 g/m2 | 80-150g/m2 |

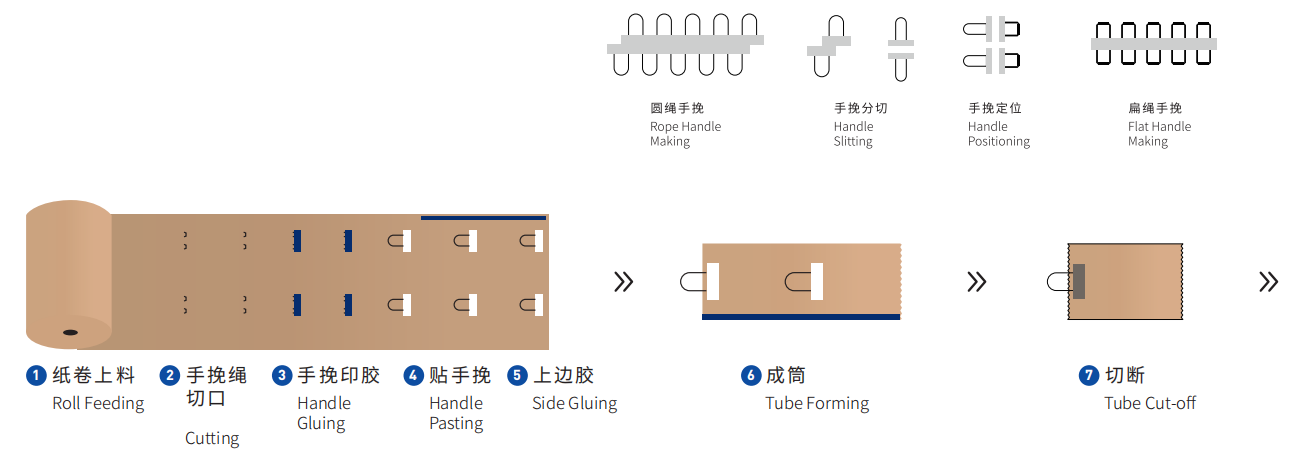

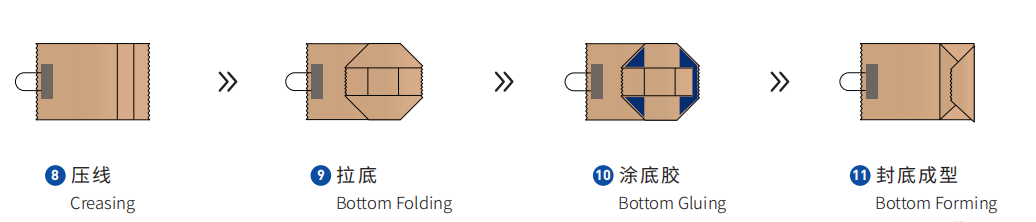

Process flow

Related Products

Get Free Product Quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call our service hotline

Nanjing Zhuoneng Machinery Equipment Co., Ltd.

Address: No. 1

, No. 63 Gutan Avenue, Gaochun Economic Development Zone, Nanjing Tel:

Fax: 025-57355788

Mobile Phone:

Mailbox:

Copyright©2023 Nanjing Zhuoneng Machinery Equipment Co., Ltd.